Energy Step Code and ERVs

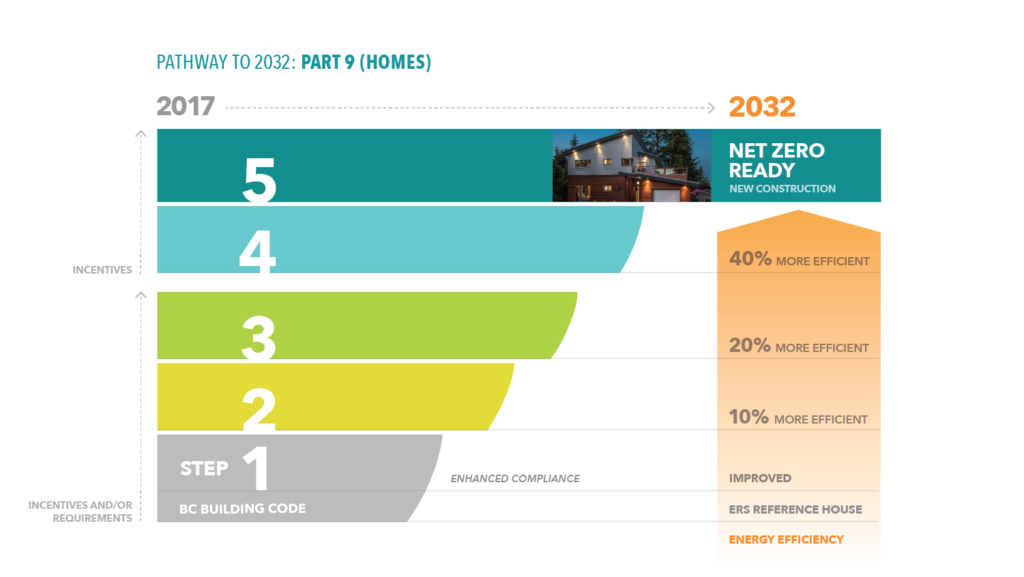

The B.C. Energy Step Code is in full swing, and regardless of whether your municipality is implementing only ‘Step 1’ currently, the movement for higher ‘Steps’ for Part 9 (Home Building) construction is on the rise. Many municipalities have already or are shortly to implement ‘Step 3’ (a 20% improvement from baseline).

Due to the Performance vs. Prescriptive nature of B.C. Energy Step Code, Builders are given opportunity to design in more unique ways that allow them to meet the energy-efficiency targets. One of the easiest ways to improve performance in energy modeling tests, is through ventilation.

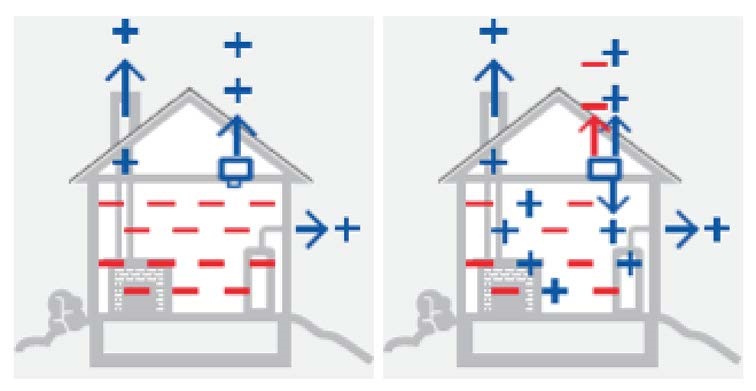

Traditional ventilation of a house relies only on exhausting air both to rid the house of excess moisture, and to provide the necessary air exchanges to maintain a healthy Indoor Air Quality (IAQ). The air that is exhausted then needs to be replaced by new air. This usually comes from the inherent leaks in the design of the house: from door frames, attic spaces, and joints in general. But as builders aim for more and more efficient designs of houses, leaks become a problem, and suddenly the supply of air to replace the exhausted air becomes a design flaw.

Enter the ERV

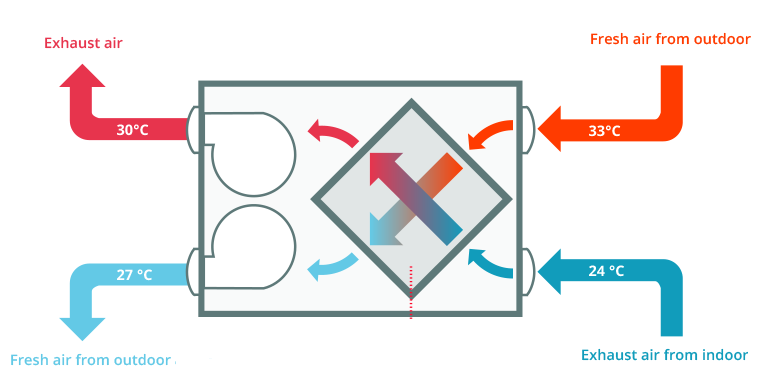

An ERV (Energy Recovery Ventilator) both Supplies and Exhausts air, providing the ability to set precisely how much air is to be brought in and out of the home. More than just providing air movement and air exchanges to maintain a health IAQ, an ERV ‘tempers’ the air being supplied with the pre-heated air that is being exhausted. this allows for the ‘Recovery’ of the energy spent to heat the indoor air.

HRV vs ERV?

Traditional HRV (Heat Recovery Ventilators) provide all of the above mentioned functions, but use a plastic-based core in order to transfer heat between incoming and outgoing air. This comes with the major downside of not also transferring moisture between the two air streams. With nowhere to go, the moisture collects and needs to be drained, meaning extra design requirements to removed the unwanted moisture buildup.

Due to the paper-based capillary core in Panasonic’s Intelli-Balance ERV, both heat and moisture can be transferred between the supply and exhaust air streams. Not only does this remove the need to drain excess moisture, but it also allows for the cooling of incoming air, allowing you to save energy in both the heating AND cooling of your house.

(Image from zeroenergyproject.org)

From a design perspective, that means that the Intelli-Balance ERV allows you to show marked improvements in your Energy Modeling reports in both for both heating seasons AND cooling seasons, leaving your home markedly more efficient. For a more in-depth look at the installation of the Intelli-Balance ERV, check out the Case Study done by Riviera Electric.

So Now What?

With the opportunities for unique and performance driven design, the Intelli-Balance ERV offers an excellent solution to the traditional ventilation design and significant energy savings over an ordinary HRV. Have any questions on design or function? Curious to know how an ERV could be implemented in your next build? We’d be happy to discuss!